INVEST IN PRECISION

VIBRATION COMPENSATED COHERENCE SCANNING INTERFEROMETRY SYSTEMS

EXISTING QUALITY ASSURANCE LACKS EFFICIENCY

Optical measurement technology is a critical enabler of modern innovation and a primary solution for achieving precise measurements in quality assurance.

However, existing optical measurement systems require vibration isolation, making them unsuitable for integration within production processes.

Scrap production

Post-production quality inspections can increase scrap rates, driving up costs and reducing profitability and sustainability.

Manufacturing downtime

The removal of workpieces for inspection under laboratory conditions results in significant time loss.

Sampling inspections

Sample inspections can miss defects, lead to inaccurate quality assessments, and introduce inefficiencies due to limited sample sizes and potential process disruptions.

Specialized labs

Costly laboratory inspections demand more time, specialized staff, and careful logistics, with limited flexibility.

MEASURE EVERYWHERE

We embed precise optical measurement technology directly into the production.

Reducing manual effort to a minimum and boosting efficiency for a more sustainable workflow.

In-situ application

Analyze process data to measure and adjust the production workflow during operation.

100% Quality Assurance

Meet the standard for every product, reduce defects, enhance customer satisfaction, and minimize costly recalls or rework.

Lower tolerances

Enhancing the precision and quality of manufactured products, reducing variability, improving functionality, and ensuring consistency in production.

Established core

Coherence scanning interferometry is a well-established technique for surface measurements. We adapt it for versatile use within industrial standard applications.

We are backed by more than 10 years of research and development at the University of Kassel.

GOING FURTHER

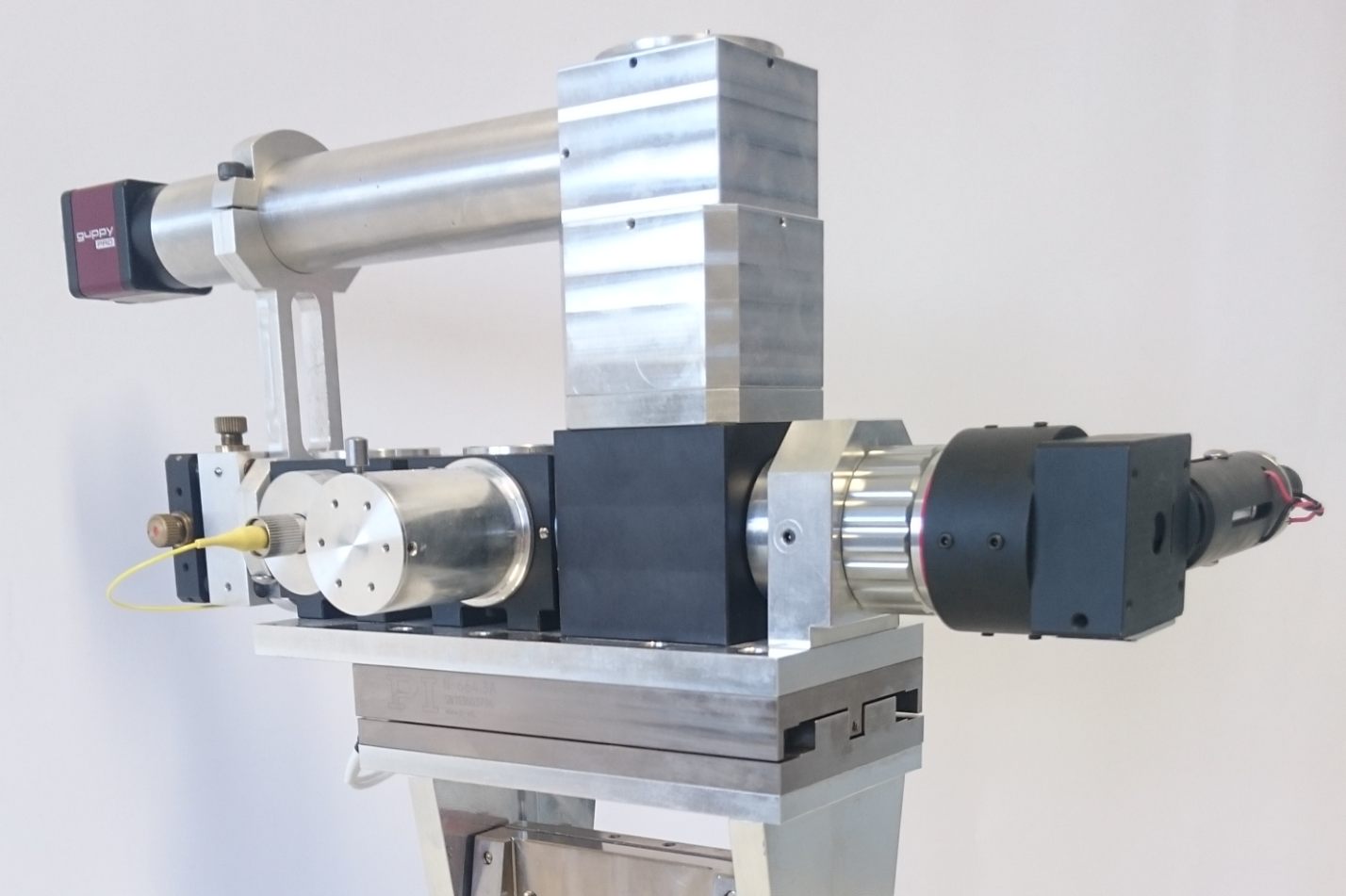

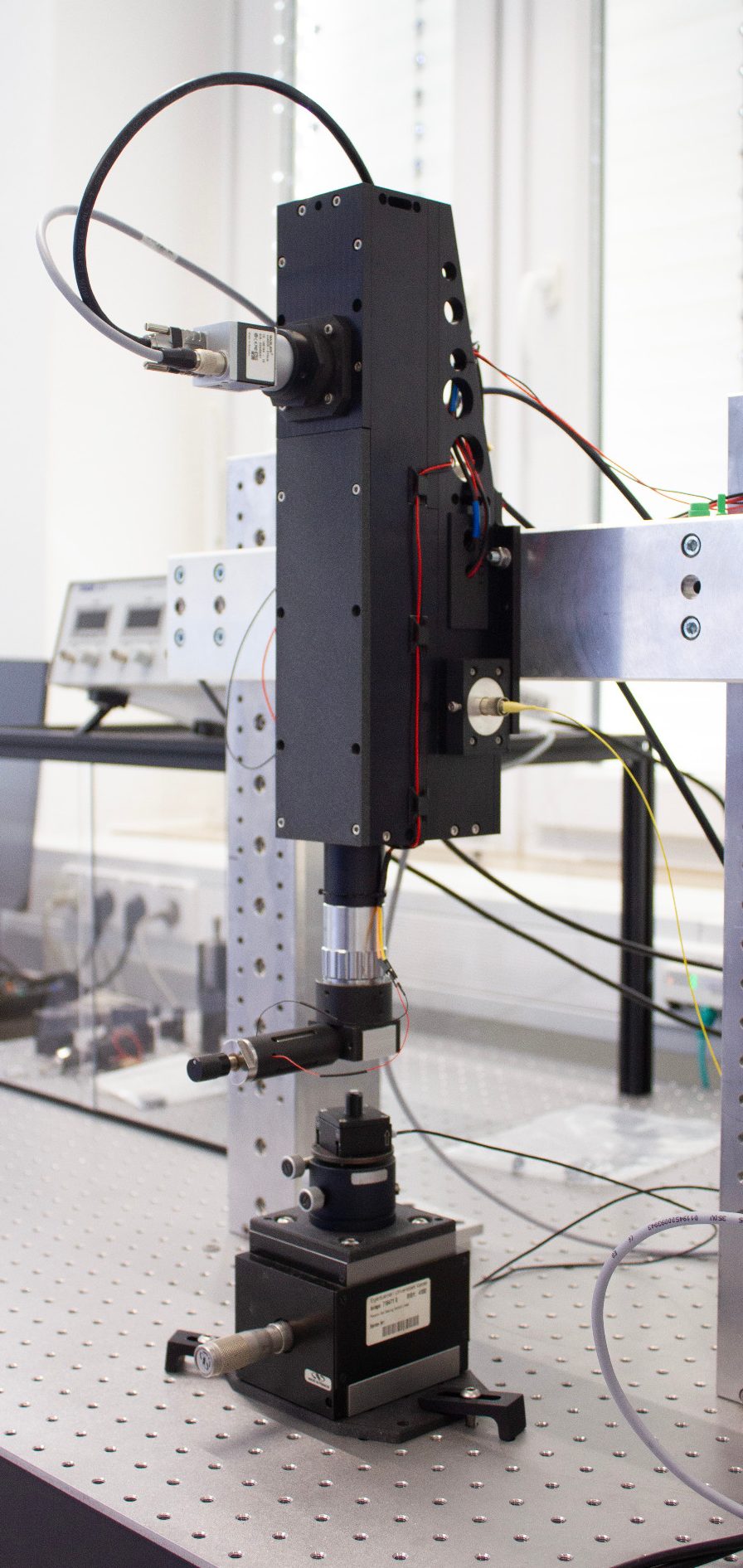

Why settle for traditional methods when you can enhance them for even better results? This is the approach we took in developing our system. We built upon the established technology of coherence scanning interferometry (CSI) by incorporating interferometric measurements of the surrounding vibrations that negatively affect or corrupt the optical measurement. To achieve this, we utilize an interferometric distance sensor (IDS). Both technologies are seamlessly integrated with our sophisticated software, delivering consistent and accurate measurement results.

Our solution translates this fundamental concept into a practical implementation by integrating a optomechanical unit, electronic hardware, and a powerful software into a cohesive system. The optomechanical unit is specifically designed to suppress optical aberrations, while the electronic hardware ensures precise synchronization between sensor signals and optical data. Moreover, the software incorporates a unique algorithm that effectively eliminates disturbances of a continous manner aswell as impulsive ones, e.g. caused by incidental mechanical impacts, such as a hammer strike on the measurement table.

We can find place in any productional situation that requires contactless, high-precision measurements without the constraint of time-consuming handling from place to place. Instead of checking after the fact whether a process was successful, we actively intervene to optimize it while it is running.

WE ARE METUBIQ

Hüseyin Serbes

M.Sc. Medical Technology

Andre Stelter

M.Sc. Electrical Engineering

Alexander Metzker

B.Sc. Electrical Engineering

FUNDED BY

We have rebranded from WaveVision to Metubiq. Alongside this transition, we have also developed a cohesive new corporate design to reflect our updated identity.

We are delighted to announce that we have been honored as winners of this year’s Hessen Ideen Contest. This achievement would not have been possible without the invaluable support and encouragement of those who believe in us and continue to do so throughout this journey.

(Foto: Hessen Ideen/ Mario Andreya)

We have successfully obtained funding from the prestigious EXIST Transfer of Research program, providing us with the resources to accelerate our innovation. This funding will enable us to further develop and commercialize our groundbreaking vibration-compensated white-light interferometry systems. (Foto: UNIKAT Kassel/ Michelle Haupt)

Contact

Telefon: +49 561 804-6503

E-mail: Mail

Anschrift:

Hüseyin Serbes

Universität Kassel

FB16 Elektrotechnik/Informatik

Fachgebiet Messtechnik

Wilhelmshöher Allee 71

D-34121 Kassel

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.